|

AUBO SDK

0.26.0

|

|

|

|

|

AUBO SDK

0.26.0

|

|

|

|

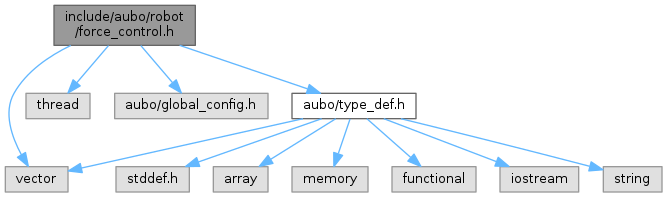

Go to the source code of this file.

Classes | |

| class | arcs::common_interface::ForceControl |

Namespaces | |

| namespace | arcs |

| namespace | arcs::common_interface |

Typedefs | |

| using | arcs::common_interface::ForceControlPtr = std::shared_ptr<ForceControl> |

Force control interface

Force control limitations When the robot is force controlled, the following functionality is not accessible:

• Collision Detection (option 613-1)

• SoftMove (option 885-1)

• Tracking functionality like Conveyor Tracking (option 606-1), Optical Tracking (6601) and Weld Guide (815-2)

• Sensor Synchronization or Analog Synchronization

• World Zones (option 608-1)

• Independent Axes (option 610-1)

• Path Offset (option 612-1)

• Arc options

• PickMaster options

• Joint soft servo (instruction SoftAct)

• Force Control cannot be activated when the robot is running in MultiMove Coordinated mode (option 604-1).

• If Force Control is used together with SafeMove (option 810-2) or Electronic Position Switches (option 810-1), the function Operational Safety Range must be used. See the respective manual for these options.

• RAPID instructions such as FCAct, FCDeact, FCConditionWaitWhile and FCRefStop can only be called from normal level in a motion task.

Applications: polishing, grinding, cleaning

FC Pressure

Set the z direction of the trajectory coordinate system as the force control axis, set spring to 0

Before contact, set output force to 0, spring to a fixed value (determined by vel)

Leaving the contact surface: set output force to 0, spring to a fixed value

Piston assembly

Forward clutch hub

Set force control termination mode

Drag teaching based on end force sensor

spring = 0; force_ref = 0; reference trajectory point arbitrary

Definition in file force_control.h.